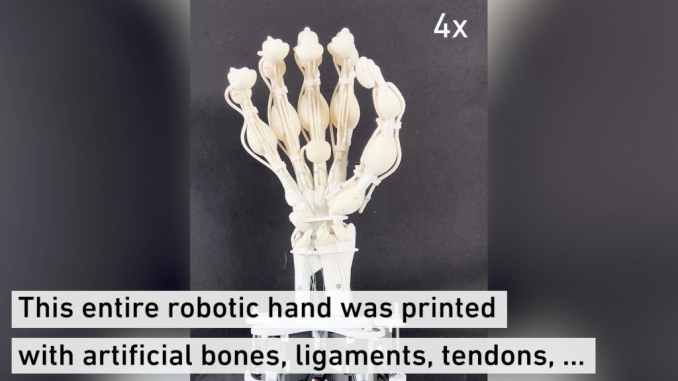

A robotic hand complete with bones, ligaments and tendons has been created for the first time using the latest 3D printing technology.

Scientists have rapidly expanded the possibilities of soft robotics – thanks to a new technology that combines 3D printing with a laser scanner and a feedback mechanism.

A spin-off in the US now offers the technology and prints complex objects on customer request.

While 3D printing technology was previously limited to fast-curing plastics, researchers have now made it suitable for slow-curing plastics as well.

They say these materials have “decisive” advantages as they have enhanced elastic properties and are more durable and robust.

The use of such polymers is made possible by new technology developed by researchers at ETH Zurich in Switzerland and a US start-up company.

As a result, researchers can now 3D print complex, more durable robots from a variety of high-quality materials in one go.

The technology also makes it easy to combine soft, elastic, and rigid materials.

The researchers can also use it to create delicate structures and parts with cavities as desired.

Using the new technology, scientists at ETH Zurich have succeeded for the first time in printing a robotic hand with bones, ligaments and tendons made of different polymers in one go.

Study first author Thomas Buchner, a doctoral student in the group of ETH Zurich robotics Professor Robert Katzschmann, said: “We wouldn’t have been able to make this hand with the fast-curing polyacrylates we’ve been using in 3D printing so far.

“We’re now using slow-curing thiolene polymers. These have very good elastic properties and return to their original state much faster after bending than polyacrylates.”

He said that makes thiolene polymers ideal for producing the elastic ligaments of the robotic hand.

Katzschmann explained that the stiffness of thiolenes can be “fine-tuned” to meet the requirements of soft robots.

He said: “Robots made of soft materials, such as the hand we developed, have advantages over conventional robots made of metal.

“Because they’re soft, there is less risk of injury when they work with humans, and they are better suited to handling fragile goods.”

Usually, 3D printers produce objects layer by layer: nozzles deposit a given material in viscous form at each point; a UV lamp then cures each layer immediately.

To accommodate the use of slow-curing polymers, the researchers developed 3D printing further by adding a 3D laser scanner that immediately checks each printed layer for any surface irregularities.

Study co-author Professor Wojciech Matusik, of Massachusetts Institute of Technology (MIT) in the US, said: “A feedback mechanism compensates for these irregularities when printing the next layer by calculating any necessary adjustments to the amount of material to be printed in real-time and with pinpoint accuracy.”

He said that means that instead of smoothing out uneven layers, the new technology simply takes the unevenness into account when printing the next layer.

Inkbit, an MIT spin-off, was responsible for developing the new printing technology.

The ETH Zurich researchers developed several robotic applications and helped optimize the printing technology for use with slow-curing polymers.

The researchers from Switzerland and the US jointly published the technology and their sample applications in the journal Nature.

Now Katzschmann’s group plans to use the technology to explore further possibilities and to design even more sophisticated structures and develop additional applications.

Inkbit is planning to use the new technology to offer a 3D printing service to its customers and to sell the new printers.

Produced in association with SWNS Talker